Picture taken from Dynaudio's website

Speakers - More than meets the Eye (Part 3)

By Jason

( Hehehe...

the same intro again... yeah... i am using the same intro paragraphs for this

series of speaker design articles... : ) so ignore the paragraphs below if you

already read the article in Part 1 )

<ignore>

There

are a lot of factors which combine to make a good-sounding loudspeaker, the

making of which is still a black art. There are, however, certain fundamentals

that we can draw upon to evaluate a loudspeaker's technical design, and thus

have an idea of the potential of its sound. No, I'm not saying that a technically

well-designed loudspeaker will sound good, simply that it has the potential

to sound good. Conversely, a technically ill-designed loudspeaker has similar

potential to sound bad!

Speaker Crossover

Within the piano-glossed, solid MDF (medium density fibre-board) speaker cabinets, behind the esoteric drivers, lie one of the integral components of loudspeakers - the crossover. Simply put, the crossover accomplishes the task of passing the "correct" frequency range of electrical signals to each driver (I.E., woofer receives bass, tweeter receives treble frequencies). It ensures the synergy of the drivers working as a whole to form a loudspeaker.

Picture taken from Dynaudio's website

</ignore>

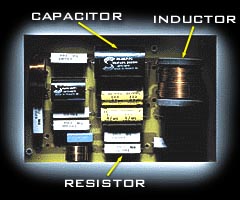

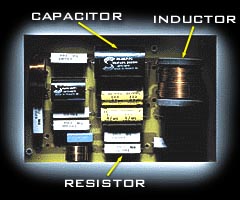

The illustration above shows a conventional crossover, whose main parts are capacitors, inductors and resistors (Some cross-overs may include tweeter protection circuitry and other frills). These 3 main types of components, when connected in a special way, produces the required crossover.

About Capacitors (Abbrv.: Caps)

Capacitors are charge-storing devices. In speaker crossovers, they serve to block out low frequencies to the speaker drivers. For the layman, capacitors only present 1 attribute, that is capacitance (measured in microFarads for speaker caps, the voltage rating is usually much higher than is required and can thus be ignored in conventional speakers).

Speaker capacitors come in various types. The more popular ones being electrolytic (non-polar ... please!), mylar, (metallized) polypropelene and polystyrene (plastic film) caps. There are even some exotic caps using teflon in its construction. If there is only 1 value, i.e. capacitance, why do we bother with having so many different types of caps?! The simple answer is that they all sound different. Some caps sound "slow" and veiled, whereas others sound "fast" and transparent. They all add different characteristics to the sound produced, thus IMHO, proper selection of caps is required on the part of the speaker designer to produce a good sounding speaker. Yet there are many speaker manufacturers who place cost as their top priority and use the cheapest parts available.

Capacitors

can have applications in both the high pass (tweeter) and low pass (woofer)

crossover sections. Thus, in speakers using such crossovers, both high and low

frequencies are affected by the capacitor that is used. The most important capacitors

are the ones in series with the tweeter. These, when changed, can have a very

appreciable effect on the sound of a speaker. In general, capacitors

(components) that are in series with the drivers affect sound more than those

in parallel with the drivers.

( In my earlier article about inductors, you might have gotten the idea that

the only thing affecting bass is the bass inductor ... NO, capacitors in the

bass sections of the crossover also affect the bass by quite a considerable

extent, it's just that the inductor, being in series with the bass driver, makes

a bigger difference. Similarly, inductors may also be used in parallel with

the tweeters, but play less of a major role than the series caps)

Capacitors can also be changed, sort of like tubes in a tube amp... although

some soldering skill is needed. Yes, it is fun to change caps and appreciate

the CHANGES in sound. But it takes an experienced person to know what caps to

use in a particular speaker to tweak the sound towards his liking, otherwise,

I foresee a little fortune being spent on changing caps! Knowing which caps

to change to have the greatest effect, and what caps to use, require knowledge

that comes from both personal experience and reading about others' experiences

(that's what the Internet is about : ).

(Disclaimer: NO, I am not asking you to open up your speaker and change

them... for a little knowledge is a dangerous thing. But it is possible for

one to tune the sound of speaker towards his liking by changing caps...)

About Resistors

Resistors can be found in many speaker crossovers, usually to match one driver's loudness to that of another (They also have applications in other more complex crossover circuits that I shall not elaborate on here). Resistors have the attribute of resistance (measured in Ohms). Once again, despite having only 1 useful attribute that we commonly know, they all sound different. All these make speaker crossover design seem like a black art ... it is ... in some ways. Again there are several types of resistors, eg. wire-wound, carbon, metal foil, etc. . In speakers, the wire-wound resistor is favoured by some for the large surface area of the actual conductor within the resistor. To me, whichever resistor gives me the sound that I like best, IS the best, in that particular application.

Crossover ( Effect of Vibrations / Layout design / Etc... )

Yes,

crossovers are affected by vibrations, just like all hifi equipment. It is good

if a crossover is isolated from these devils. In examples such as Wilson Audio,

Sonus Faber, (some of) their speakers have isolated crossovers that are potted

in resin (such as epoxy). The worse place to locate a crossover, where vibration

control is concerned, is actually directly behind the drivers. Yet, this is

the most common place for manufacterers to site their crossovers, for it also

has the obvious benefit of having shorter internal speaker wiring. (There are

always pros and cons, a good design can perhaps alleviate both problems...)

I feel that the best place for a crossover is OUTSIDE the speaker, in its own

separate damped enclosure. Some crossover components are less susceptive to

vibrations than others, but it is no harm to isolate them from vibrations as

well.

Crossover components can also interact with one another, especially so for inductors

due to their magnetic fields. In theory, inductors should be as far apart as

possible, and they should be at 90 degrees to one another to minimise magnetic

field interactions. This is another reason why crossovers should not be directly

behind the drivers themselves, for the drivers also have magnetic fields that

will mutually interact with these crossover components and degrade sound. Caps

are also affected, but to a smaller extent.

I personally prefer crossovers that are hard-wired, for these have less solder

joints and also have less signal running through PCB traces (Printed Circuit

Board). Many manufacterers use PCBs as they are easier to assemble.

Conclusion

This is the conclusion for this article, which is

essentially an introduction itself to speaker crossovers. There is a lot more

to the crossover than what is mentioned here, but I hope this article gives

you somewhere to start reading, before you embark on reading more about them.